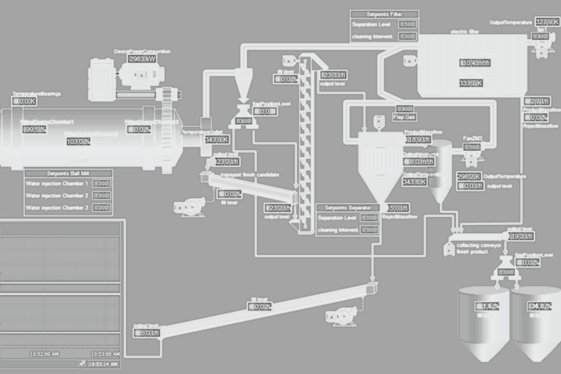

The current situation and possible future scenarios for the industry in the light of Industry 4.0 were investigated in the context of a study carried out in 2018 (open here). The results of the study revealed that at the companies asked almost all information is available and can be transmitted in digital form. This means that the requirements for the digitisation of processes in the cement industry, which is the basis for Industry 4.0, are largely satisfied. What's more, certain automated process steps such as clinker manufacture or cement grinding have reached an even higher degree of Industry 4.0 maturity. Control of these processes is already largely autonomous at the plants, with continuous monitoring in the control room. As a general rule employees only have to actively intervene in the case of critical situations.

The cement industry faces the following broader challenges with regard to the implementation of Industry 4.0:

- Shortage of skilled personnel: Most companies are already having difficulty finding enough employees with information technology skills and the demand is still rising.

- Internet access: An inadequate internet bandwidth at the plant locations is often an obstacle to greater utilisation of Industry 4.0 applications.

- Data security reservations: Another factor limiting the widespread use of web-based solutions is concern about data security, in relation to the use of cloud services for example.