Assessment of deposits

- Screening of potential deposits or evaluation of existing data

- Geological and geostatistical data analysis and modelling

- Sampling of drill cores and current mining

- Analyses to assess the quality and homogeneity of a deposit

- Qualitative risk assessment of deviating clay qualities and recommendations to manage such deviations (stockpiling, homogenisation, etc.)

Chemical-mineralogical characterisation of raw materials

- Professional sample preparation

- Determination of the chemical-mineralogical composition by means of XRF, XRD and wet chemical methods

- Determination of critical parameters (heavy metals, sulphur, TOC, fluoride etc.)

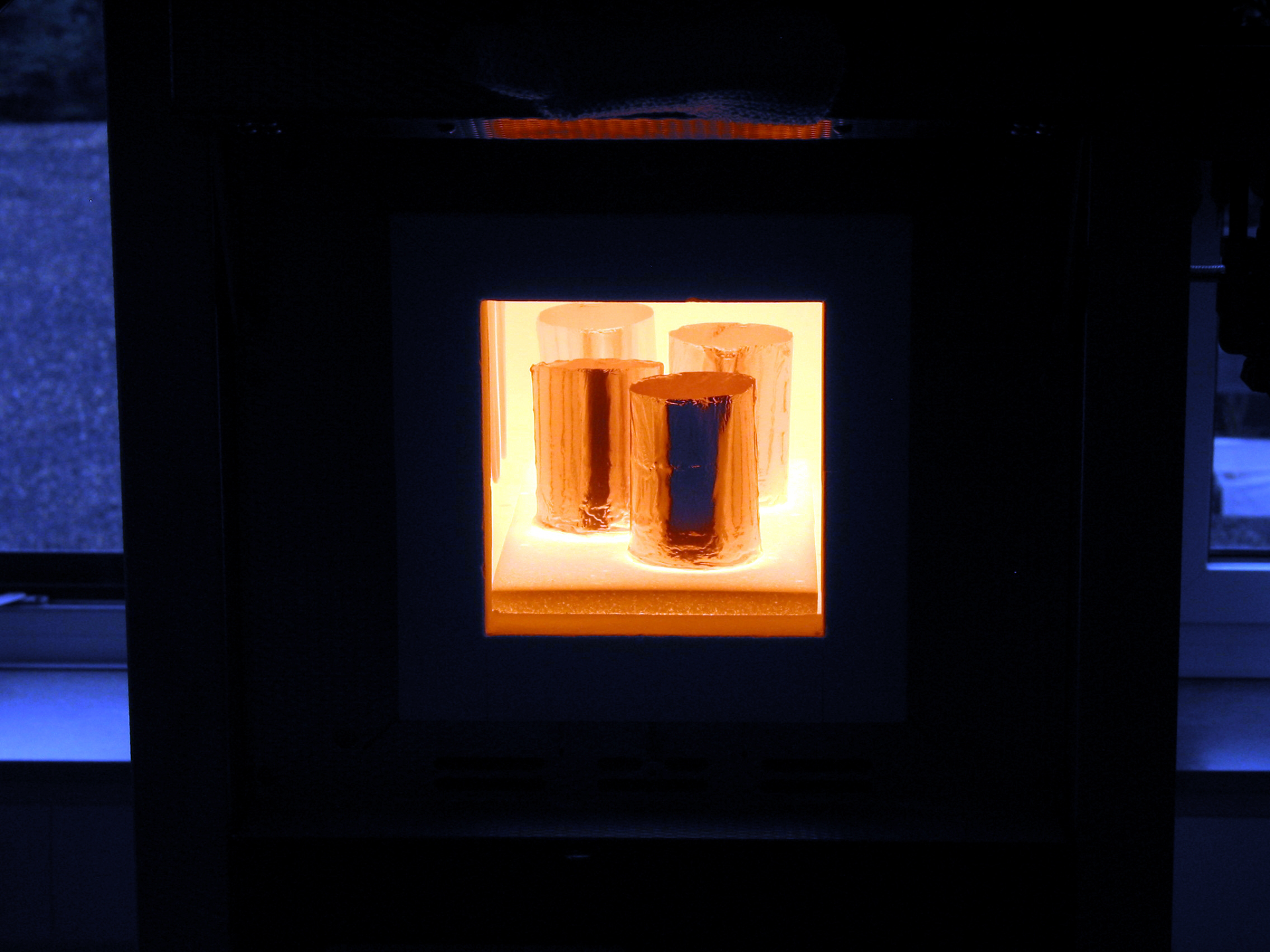

Determination of suitable calcination conditions

- Laboratory-scale tests under consideration of the clay mineralogy and the pozzolanic potential of the clay

- Control of the calcining process by X-ray diffraction analysis

- Reactivity tests according to EN 197-1 and other methods

- Determination of the optimum calcination conditions with regard to temperature and kiln atmosphere (if necessary, avoidance of colouring components)

- Calculation of raw material-related CO2 emissions

Performance test of the calcined product in cement and concrete

- Calcination of larger sample quantities

- Grinding of the samples to a requested fineness

- Determination of the particle size distributions and of the specific surface area acc. BET of the calcined products

- Production and testing of clay containing cements according to EN 196-1, -3 and other standards

- Determination of the activity index according to EN 450-1

- Investigation of the fresh and hardened concrete properties as well as the influence of ad-mixtures and parameters relevant to durability

- Assessment of the discolouration potential in mortar and concrete

Determination of emission-relevant parameters

- Volatilisation tests at different atmospheres under consideration of the optimal calcination conditions for the respective clay

- Determination of volatile organic hydrocarbons (VOC), carbon monoxide (VCO), sulphur dioxide (VSO2) and other parameters as a function of temperature and gas composition

- Preparation of emission forecasts

Plant design and process implementation

- Support in communication with the plant manufacturer in raw material and cement specific questions

- Set up of quality assurance concepts

- Support in the implementation of necessary management systems

- Emission measurements in accordance with the applicable environmental law requirements by our accredited measuring body

Support for the development / market launch of cements containing clay

- Development of clay containing cements taking into account normative and customer-specific requirements, e.g. strength class

- Creation of presentations and/or brochures for market launch and customer acquisition

- Monitoring of European Approval Procedures (ETA)

- Quality monitoring of clay containing cements