a) Determination of raw material-induced emissions

High temperatures are required for the production of cement clinker. This involves the burning of fossil and alternative fuels in the main and, if applicable, the secondary firing system of the kiln plant. Various airborne pollutants, for which emission limits have to be met, are formed in this process. Certain airborne pollutants do not however only occur within the combus-tion process, they may also be released during heating of the raw meal in the preheater. This applies for instance to the ex-haust gas components SO2, NH3, CO, total carbon and also mercury.

The authorities concerned can make exceptions from the relevant emission limits for those exhaust gas components which primarily originate from the raw material ("raw material-induced emissions"), as these depend on the raw material available at the site and are thus unavoidable. Owners generally have to provide information on the level of raw material-induced emissions when applying for such exceptions.

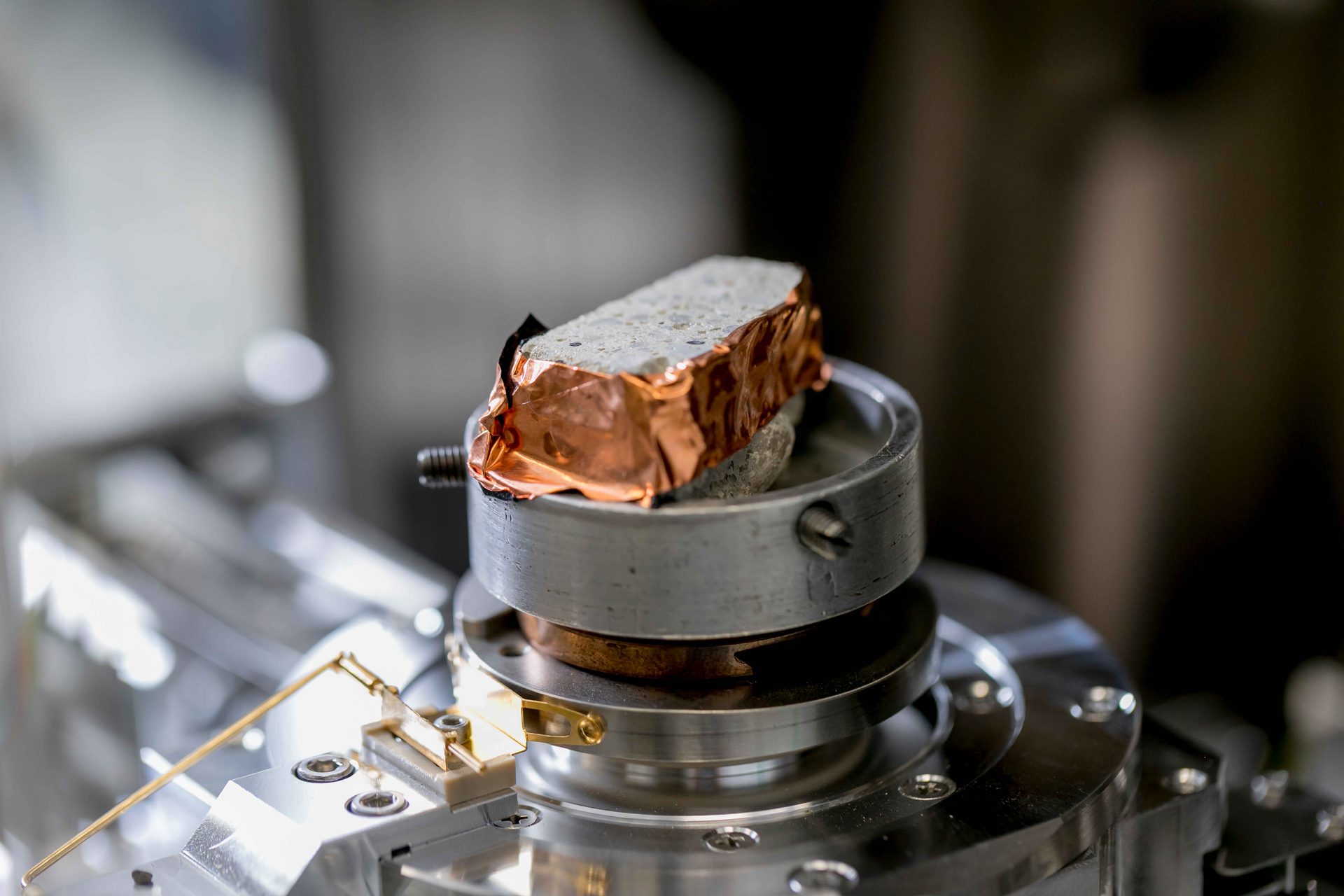

Samples of the naturally occurring raw materials are analysed at the VDZ laboratories to determine the level of raw material-induced emissions. Following appropriate treatment, the samples are heated under controlled conditions in a laboratory kiln ("gas liberation apparatus") in a raw gas-like atmosphere and the airborne pollutants released in the process are measured either continuously or intermittently. The level of the raw material-induced emissions can be established from these results and further necessary data from the rotary kiln plant of the cement works.

b) Analysis of aqueous solutions for organic and inorganic substances

Today we make use of a wide range of methods offering excellent verification for the analysis of organic and inorganic substances in aqueous solutions. Following appropriate sample preparation, we employ a combination of gas chromatography and mass spectrometry (GC-MS) to determine organic substances such as polycyclic aromatic hydrocarbons (PAH) or highly volatile aromatic hydrocarbons (BTEX). Trace elements – from antimony to zinc – are usually determined using the extremely high-performance inductively coupled plasma mass spectrometry (ICP-MS) method. For mercury we continue to apply the reliable atomic absorption spectrometry (AAS) process. Calcium, sodium, potassium and the common anions chloride, sulphate and fluoride are quantified by means of ion chromatography (IC).

c) Release of trace elements from solids

The regulations set down in the applicable European and domestic legislation must be observed with regard to the trading and use of construction products. The environmental compatibility and safety of the construction products used must be guaranteed, particularly in the case of building work in ground-water and soil as well as in the drinking water sector. On account of their favourable properties (great durability and impermeability, low substance emissions), use is often made of cement-bound construction products in hygienically sensitive areas as well.

Leaching tests can be employed to verify the environmental compatibility of construction products. These determine whether the substances emerging from the construction products satisfy the stipulated requirements. VDZ has many years of experience in the assessment of the environmental compatibility of cement-bound construction products and has already conducted a number of projects aimed at further enhancing existing analytical methods at its research institute. Right from the product development stage we can advise our customers on the topic of environmental compatibility and perform extensive testing and trials for the assessment of environmental compatibility.